Management of Water Discharge and Air Emission in Oil/Gas/Energy Industries

Introduction

Water & wastewater treatment infrastructure plays a critical role in human water consumption cycle. Water treatment ensures fresh water quality to protect public health and to support sustainable urban development. Wastewater treatment alleviates adverse environmental impacts and ecological effects caused by waterborne pollutants generated by human activities.

Application of advanced treatment technologies and integrated water resources management help mitigate the challenges in global freshwater availability, industrial water risks and agricultural water use for food production.

Dr. Lin’s Water Research Laboratory at Lamar University focuses on the development, design, and implementation of conventional and advanced treatment systems, as well as optimization and management of industrial water use.

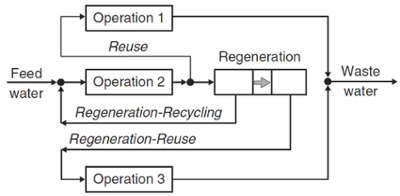

Water Reuse, Recycle & Regeneration

Opportunities exist for unit operations in plants to reduce industrial water footprints and wastewater discharge. This is accomplished through process evaluation of feed water quality goals and implementation of water reuse and/or recycle through regeneration of process water.

Shirazi S., Lin C.-J., “Membrane Technology for Water Purification &Desalination,” in Sustainable Water Management & Technologies (Ed.) Chen D., Taylor&Francis/CRC Press, Boca Raton, FL, 2015.

Process diagram – optimization of in-plant water consumption.

Air Emission Reduction through Process Optimization

Optimization of unit operations in petrochemical plants brings about benefits of increased productivity, reduced air emission, better energy efficiency and improved process safety.

The optimization can be accomplished through process simulation incorporating various scenarios in production goals and schedules and process operational parameters that lead to industrial flaring minimization. The air mission outcomes from the simulation results will then be applied for assessment on air quality impact and process modifications.

Plant Flare Minimization

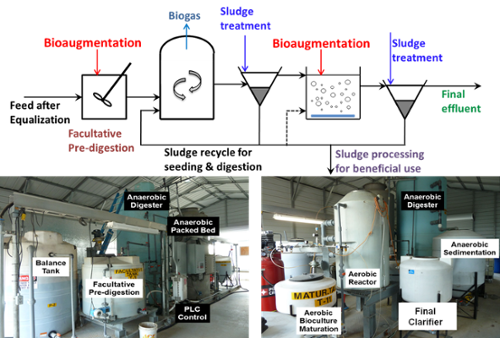

Anaerobic Digestion of Organic Wastes

Anaerobic digestion converts biodegradable organic substrates into CH4 (biogas) and CO2 in the absence of O2. The process effectively recovers renewable energy from organic streams such as agricultural wastes and municipal wastewater sludge.

Recent developments in bio-augmentation and process engineering allow anaerobic digestion of relatively recalcitrant industrial wastes, and enables waste-to-energy conversion at commercial scale for industrial processes that produce concentrated organic waste streams.

Zhang P., Lin C.-J. et al., "Biogas production from brown grease using a pilot-scale high-rate anaerobic digester," Renewable Energy, DOI: 10.1016/j.renene.2014.01.046, 2014.

Pilot-scale evaluation for anaerobic digestion of brown grease.

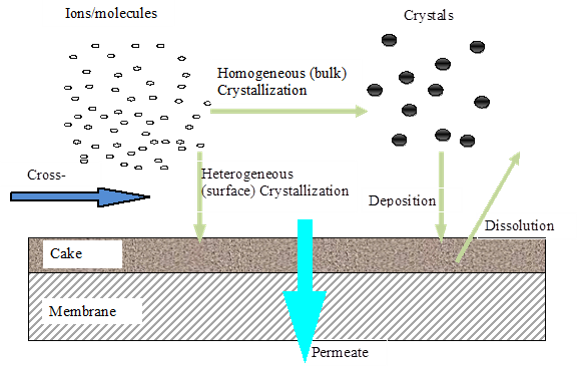

Membrane Filtration

Pressure-driven membrane process uniquely addresses multiple needs in global water sustainability. Advancement of new-generation, low-pressure-requirement membranes has also led to renewed applications in wastewater treatment that substantially improves the effluent quality for secondary water reuse and irrigation. Membrane filtration process reduces the number of unit operations and simplifies the treatment train.

Additional advantages, such as selective separation, continuous and automatic operation, easy scale-up and low space requirement, make membrane filtration an attractive alternative to address sustainable water needs.

Shirazi, S., Lin, C.-J., Chen, D., Inorganic fouling of pressure-driven membrane processes - A critical review. Desalination 2010, 250, (1), 236-248.

.

.

Schematic of membrane filtration and relationship between filtration performance (rejection) and operational parameters.

Decentralized Treatment Systems

Decentralized systems improve resilience of water infrastructure, and address treatment need & environmental protection for special applications and during disaster relief. Lamar water research develops fast-deployable systems for forward operating bases.

Chen D.; Lin C.-J. et al., “A deployable decentralized biofilm system for wastewater treatment.” Environ Prog Sustain Energy, 32(3), 505-511, 2013.

Decentralized wastewater treatment system

Associate Director for Programs

R. Gavin Jones, REP

Phone: (409) 880-8447

Email: Gavin.Jones@lamar.edu

Address

211, Redbird Ln., ML 10088

Center for Advances in Water & Air Quality

Lamar University

Beaumont, TX 77710-0088